Page 106 - 2020Taiwan Food and Drug Administration Annual Report

P. 106

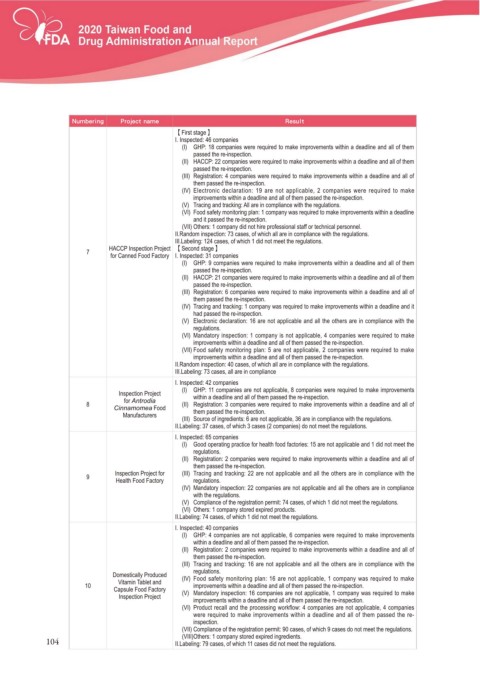

/VNCFSJOH 1SPKFDU OBNF 3FTVMU

First stage

I. Inspected: 46 companies

(I) GHP: 18 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 22 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Registration: 4 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

(IV) Electronic declaration: 19 are not applicable, 2 companies were required to make

improvements within a deadline and all of them passed the re-inspection.

(V) Tracing and tracking: All are in compliance with the regulations.

(VI) Food safety monitoring plan: 1 company was required to make improvements within a deadline

and it passed the re-inspection.

(VII) Others: 1 company did not hire professional staff or technical personnel.

II.Random inspection: 73 cases, of which all are in compliance with the regulations.

III.Labeling: 124 cases, of which 1 did not meet the regulations.

7 HACCP Inspection Project Second stage

for Canned Food Factory I. Inspected: 31 companies

(I) GHP: 9 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 21 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Registration: 6 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

(IV) Tracing and tracking: 1 company was required to make improvements within a deadline and it

had passed the re-inspection.

(V) Electronic declaration: 16 are not applicable and all the others are in compliance with the

regulations.

(VI) Mandatory inspection: 1 company is not applicable, 4 companies were required to make

improvements within a deadline and all of them passed the re-inspection.

(VII) Food safety monitoring plan: 5 are not applicable, 2 companies were required to make

improvements within a deadline and all of them passed the re-inspection.

II.Random inspection: 40 cases, of which all are in compliance with the regulations.

III.Labeling: 73 cases, all are in compliance

I. Inspected: 42 companies

(I) GHP: 11 companies are not applicable, 8 companies were required to make improvements

Inspection Project

for Antrodia within a deadline and all of them passed the re-inspection.

8 (II) Registration: 3 companies were required to make improvements within a deadline and all of

Cinnamomea Food

Manufacturers them passed the re-inspection.

(III) Source of ingredients: 6 are not applicable, 36 are in compliance with the regulations.

II.Labeling: 37 cases, of which 3 cases (2 companies) do not meet the regulations.

I. Inspected: 65 companies

(I) Good operating practice for health food factories: 15 are not applicable and 1 did not meet the

regulations.

(II) Registration: 2 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

Inspection Project for (III) Tracing and tracking: 22 are not applicable and all the others are in compliance with the

9

Health Food Factory regulations.

(IV) Mandatory inspection: 22 companies are not applicable and all the others are in compliance

with the regulations.

(V) Compliance of the registration permit: 74 cases, of which 1 did not meet the regulations.

(VI) Others: 1 company stored expired products.

II.Labeling: 74 cases, of which 1 did not meet the regulations.

I. Inspected: 40 companies

(I) GHP: 4 companies are not applicable, 6 companies were required to make improvements

within a deadline and all of them passed the re-inspection.

(II) Registration: 2 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

(III) Tracing and tracking: 16 are not applicable and all the others are in compliance with the

regulations.

Domestically Produced

Vitamin Tablet and (IV) Food safety monitoring plan: 16 are not applicable, 1 company was required to make

10 improvements within a deadline and all of them passed the re-inspection.

Capsule Food Factory

Inspection Project (V) Mandatory inspection: 16 companies are not applicable, 1 company was required to make

improvements within a deadline and all of them passed the re-inspection.

(VI) Product recall and the processing workflow: 4 companies are not applicable, 4 companies

were required to make improvements within a deadline and all of them passed the re-

inspection.

(VII) Compliance of the registration permit: 90 cases, of which 9 cases do not meet the regulations.

(VIII)Others: 1 company stored expired ingredients.

104 II.Labeling: 79 cases, of which 11 cases did not meet the regulations.