Page 104 - 2020Taiwan Food and Drug Administration Annual Report

P. 104

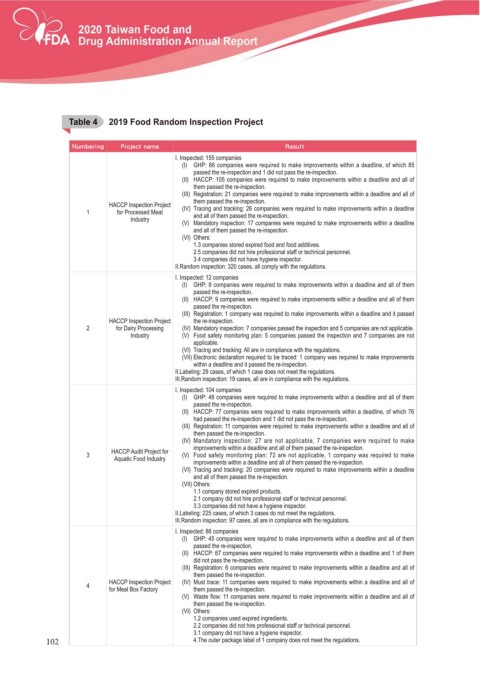

Table 4c 2019 Food Random Inspection Project

T able 4

/VNCFSJOH 1SPKFDU OBNF 3FTVMU

I. Inspected: 155 companies

(I) GHP: 86 companies were required to make improvements within a deadline, of which 85

passed the re-inspection and 1 did not pass the re-inspection.

(II) HACCP: 105 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

(III) Registration: 21 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

HACCP Inspection Project (IV) Tracing and tracking: 26 companies were required to make improvements within a deadline

1 for Processed Meat and all of them passed the re-inspection.

Industry

(V) Mandatory inspection: 17 companies were required to make improvements within a deadline

and all of them passed the re-inspection.

(VI) Others:

1.3 companies stored expired food and food additives.

2.5 companies did not hire professional staff or technical personnel.

3.4 companies did not have hygiene inspector.

II.Random inspection: 320 cases, all comply with the regulations.

I. Inspected: 12 companies

(I) GHP: 8 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 9 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Registration: 1 company was required to make improvements within a deadline and it passed

HACCP Inspection Project the re-inspection.

2 for Dairy Processing (IV) Mandatory inspection: 7 companies passed the inspection and 5 companies are not applicable.

Industry (V) Food safety monitoring plan: 5 companies passed the inspection and 7 companies are not

applicable.

(VI) Tracing and tracking: All are in compliance with the regulations.

(VII) Electronic declaration required to be traced: 1 company was required to make improvements

within a deadline and it passed the re-inspection.

II.Labeling: 29 cases, of which 1 case does not meet the regulations.

III.Random inspection: 19 cases, all are in compliance with the regulations.

I. Inspected: 104 companies

(I) GHP: 48 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 77 companies were required to make improvements within a deadline, of which 76

had passed the re-inspection and 1 did not pass the re-inspection.

(III) Registration: 11 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

(IV) Mandatory inspection: 27 are not applicable, 7 companies were required to make

improvements within a deadline and all of them passed the re-inspection.

HACCP Audit Project for

3 (V) Food safety monitoring plan: 72 are not applicable, 1 company was required to make

Aquatic Food Industry

improvements within a deadline and all of them passed the re-inspection.

(VI) Tracing and tracking: 20 companies were required to make improvements within a deadline

and all of them passed the re-inspection.

(VII) Others:

1.1 company stored expired products.

2.1 company did not hire professional staff or technical personnel.

3.3 companies did not have a hygiene inspector.

II.Labeling: 225 cases, of which 3 cases do not meet the regulations.

III.Random inspection: 97 cases, all are in compliance with the regulations.

I. Inspected: 86 companies

(I) GHP: 45 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 67 companies were required to make improvements within a deadline and 1 of them

did not pass the re-inspection.

(III) Registration: 6 companies were required to make improvements within a deadline and all of

them passed the re-inspection.

HACCP Inspection Project (IV) Must trace: 11 companies were required to make improvements within a deadline and all of

4

for Meal Box Factory them passed the re-inspection.

9 :DVWH ÀRZ FRPSDQLHV ZHUH UHTXLUHG WR PDNH LPSURYHPHQWV ZLWKLQ D GHDGOLQH DQG DOO RI

them passed the re-inspection.

(VI) Others:

1.2 companies used expired ingredients.

2.2 companies did not hire professional staff or technical personnel.

3.1 company did not have a hygiene inspector.

102 4.The outer package label of 1 company does not meet the regulations.