Page 105 - 2020Taiwan Food and Drug Administration Annual Report

P. 105

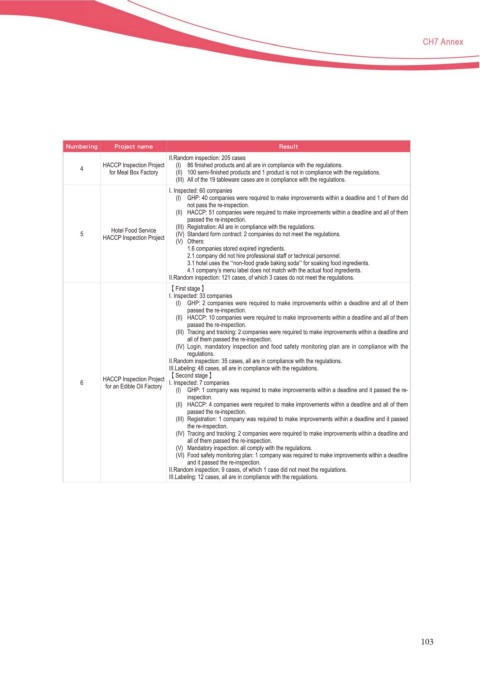

/VNCFSJOH 1SPKFDU OBNF 3FTVMU

II.Random inspection: 205 cases

HACCP Inspection Project , ¿QLVKHG SURGXFWV DQG DOO DUH LQ FRPSOLDQFH ZLWK WKH UHJXODWLRQV

4

for Meal Box Factory ,, VHPL ¿QLVKHG SURGXFWV DQG SURGXFW LV QRW LQ FRPSOLDQFH ZLWK WKH UHJXODWLRQV

(III) All of the 19 tableware cases are in compliance with the regulations.

I. Inspected: 60 companies

(I) GHP: 40 companies were required to make improvements within a deadline and 1 of them did

not pass the re-inspection.

(II) HACCP: 51 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Registration: All are in compliance with the regulations.

Hotel Food Service

5 (IV) Standard form contract: 2 companies do not meet the regulations.

HACCP Inspection Project

(V) Others:

1.6 companies stored expired ingredients.

2.1 company did not hire professional staff or technical personnel.

3.1 hotel uses the “non-food grade baking soda” for soaking food ingredients.

4.1 company’s menu label does not match with the actual food ingredients.

II.Random inspection: 121 cases, of which 3 cases do not meet the regulations.

First stage

I. Inspected: 33 companies

(I) GHP: 2 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(II) HACCP: 10 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Tracing and tracking: 2 companies were required to make improvements within a deadline and

all of them passed the re-inspection.

(IV) Login, mandatory inspection and food safety monitoring plan are in compliance with the

regulations.

II.Random inspection: 35 cases, all are in compliance with the regulations.

III.Labeling: 48 cases, all are in compliance with the regulations.

HACCP Inspection Project Second stage

6 I. Inspected: 7 companies

for an Edible Oil Factory

(I) GHP: 1 company was required to make improvements within a deadline and it passed the re-

inspection.

(II) HACCP: 4 companies were required to make improvements within a deadline and all of them

passed the re-inspection.

(III) Registration: 1 company was required to make improvements within a deadline and it passed

the re-inspection.

(IV) Tracing and tracking: 2 companies were required to make improvements within a deadline and

all of them passed the re-inspection.

(V) Mandatory inspection: all comply with the regulations.

(VI) Food safety monitoring plan: 1 company was required to make improvements within a deadline

and it passed the re-inspection.

II.Random inspection: 9 cases, of which 1 case did not meet the regulations.

III.Labeling: 12 cases, all are in compliance with the regulations.

103